BG-1218 is a dual-melting point wetting and dispersing coupling agent.

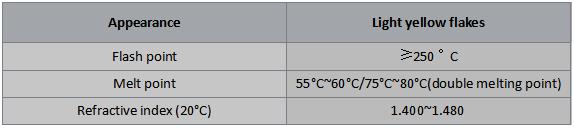

Typical physical and chemical data

Product Performance

▪ Significantly improve the dispersibility of calcium carbonate, aluminum hydroxide, magnesium hydroxide, kaolin, and titanium dioxide in polyolefin composite materials.

▪ Increase the interfacial bonding strength between inorganic powders and polyolefins, greatly enhancing the impact toughness and elongation at break of inorganic powder/polyolefin composite materials.

Typical applications

Polyolefin non-halogen flame-retardant cable masterbatch:

replacing silane coupling agent 172, it can improve the dispersibility of aluminum hydroxide (AH) and magnesium hydroxide (MH) in polyolefins, improve process flowability, and increase the tensile strength and elongation at break of wires and cables. More surprisingly, the mechanical performance retention rate of wires and cables after aging is extremely high.

Calcium carbonate masterbatch for drawing and non-woven fabrics

It can efficiently uniformly wet and disperse calcium carbonate in polypropylene, improve the interfacial bonding strength between the powder and PP, increase the strength of the thread, and reduce spinning breakage. Even in high filling systems, no powder precipitation occurs, reducing odors and harmful gases during spinning.

Breathable film masterbatch

ood dispersion of calcium carbonate in PE resin is a key factor for breathable films to meet breathability and impermeability. Excellent dispersion of calcium carbonate in PE resin is a basic requirement, and BG1218 can meet the monodispersity of calcium carbonate in PE resin and improve the quality of breathable film masterbatches.

PE pipe filling masterbatch

filling a large amount of calcium carbonate in HDPE resin will significantly reduce the environmental stress cracking resistance and impact toughness of PE pipes. Currently, the dispersants available for PE pipe masterbatches are mainly traditional products such as stearic acid, PE wax, aluminum ester coupling agents, and titanium ester coupling agents, but their dispersibility has been proven to be ineffective. BG-1218 dispersing coupling agent can fully wet the surface of CaCO3 particles and disperse them in PE resin, and the interfacial bonding strength between CaCO3 particle surface and PE resin is extremely strong, thereby achieving good processability and significantly improving the impact toughness and environmental stress cracking resistance of PE pipes.

BG-1218 can improve the dispersibility of calcium carbonate powder in polyolefins, enhance the interfacial bonding strength between powder and polyolefin substrate, greatly improve the impact toughness and strength of composite materials, and can also be widely used in polyolefin-modified household appliances and automotive composite systems.

Instructions for Use and Dosage

Unlike titanium ester coupling agents and aluminum ester coupling agents, BG-1218 is extremely easy to use and is not sensitive to water, hydroxyl compounds, or carboxyl compounds. It can be pre-processed as a powder and can also be used directly in formulations.

The recommended usage of BG-1218 is typically 0.8% to 1.5% of the powder material.

Safety Information

This product meets SGS standards and is non-toxic, odorless, free of heavy metals, and does not contain any plasticizers. It is suitable for products that come into contact with food and children.

Storage and Packaging

This product is a general chemical and should be stored as such. It should be stored in a ventilated, dry, and shaded place, with a shelf life of more than one year.

Keywords: plastic coupling agent, calcium carbonate masterbatch coupling agent, titanium dioxide masterbatch coupling agent.