SP-385 Super-Dispersant

Product Description

Calcium carbonate (CaCO3) is widely used in rubber and plastic products such as polyvinyl chloride (PVC), EVA, thermoplastic elastomers, and polyolefins (PP/PE). Due to the strong hydrophilicity of CaCO3 and poor compatibility with organic polymers, the CaCO3 powder needs to be organically modified. Currently, the following modifiers are mainly used for organic modification of CaCO3 powder:

▪ Stearic acid

▪ Titanium ester coupling agent

▪ Aluminum ester coupling agent

▪ Polyethylene wax (PE wax)

▪ Amide wax

These modifiers effectively improve the affinity between CaCO3 powder and organic polymers. However, long-term industrial applications have shown that the above organic modifiers for CaCO3 have the following disadvantages when used in rubber and plastic products:

▪ High melt viscosity during processing;

▪ Poor dispersion of CaCO3 powder in organic polymers;

▪ Significant reduction in mechanical properties of composite materials.

SP-385 is a special super-dispersant for CaCO3 used in PVC shaped materials, PVC pipes, PVC electrical conduits, PVC sheets, PVC flooring, PVC wires and cables, PVC artificial leather, PVC light box advertising fabric, PVC film, PVC wallpaper, and PVC shoe materials. SP-385 not only improves the dispersion of CaCO3 in PVC composite materials but also has good processing fluidity, improves product gloss, and reduces PVC melt viscosity. At the same time, it significantly improves the impact toughness and strength of PVC products. Additionally, SP-385 is also very effective for polyolefins (PP/PE), nylon (PA), PBT/PET, ABS, and other plastic products.

SP-385 is a new generation of efficient super-dispersant and coupling agent, replacing traditional stearic acid, titanium ester coupling agent, aluminum ester coupling agent, and PE wax dispersant.

SP-385 super-dispersant simplifies the formulation and processing technology of PVC products. Only the type (light or heavy) and fineness and whiteness of calcium carbonate need to be selected, without considering the effects of different coupling agents and processing methods chosen by calcium carbonate manufacturers on PVC processing instability and color changes.

SP-385 super-dispersant can significantly increase the filling amount of CaCO3 and achieve the goal of improving production quality and reducing production costs.

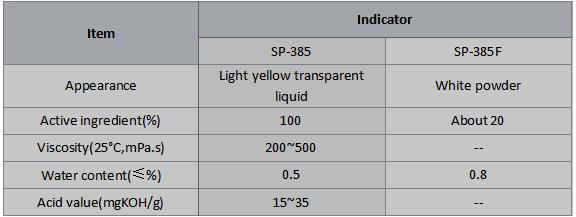

Performance indicators of SP-385 super dispersant

Note: SP-385F is a powder-type product specifically developed for convenient metering. It is recommended that users use SP-385 liquid dispersant as much as possible.

SP-385 Dosage and Usage Method

(1) SP-385 Dispersant Dosage

The dosage of SP-385 super dispersant is based on 0.8% to 1.0% of calcium carbonate.

The dosage of SP-385F super dispersant is based on 4.0% of calcium carbonate.

(2) SP-385 Super Dispersant Usage Method

SP-385 super dispersant can be used with pre-mixing method and in-situ method.

(a) Pre-mixing method

Put the CaCO3 powder into a high-speed mixer, start stirring, add SP-385 super dispersant, mix until it is discharged at 110℃, and obtain the pre-mixed coated calcium carbonate, which can be used directly in the PVC formula.

(b) In-situ method

Directly add it in the PVC mixing process: first add PVC, plasticizer (for soft products), heat stabilizer, toughening agent (for hard products), processing aid, pigments, etc., pre-mix at 80℃, then add CaCO3 powder and SP-385 super dispersant, mix until 120℃ to 130℃, and cool down and extrude (injection molding, rolling, etc.) into products.

Application of SP-385 Super Dispersant in PVC Formulation

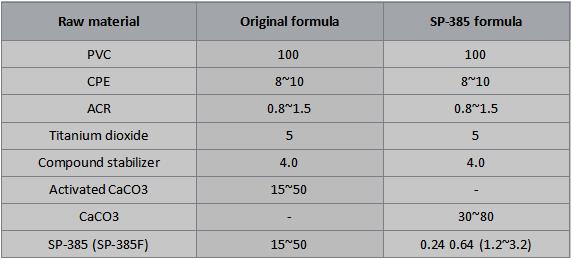

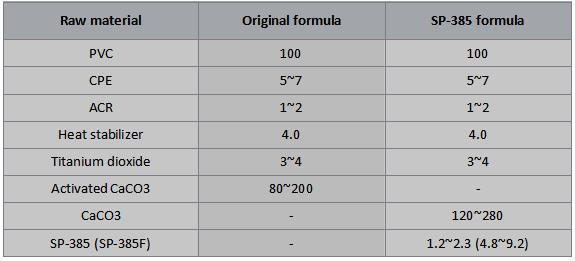

It is recommended to use for shaped profiles.

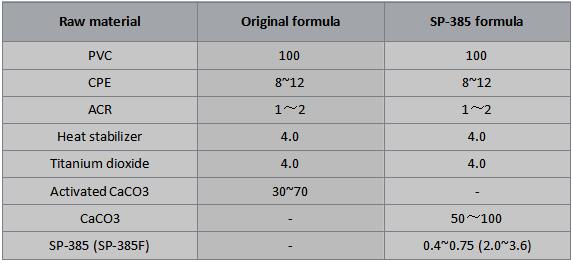

PVC electrical pipe recommended use

PVC water supply pipe recommended use

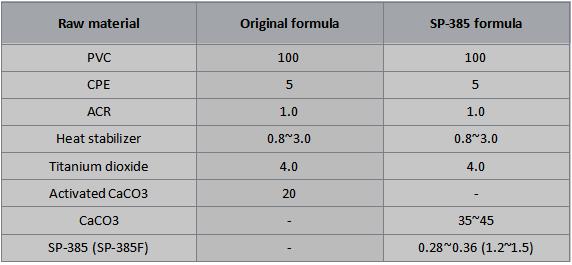

PVC drainage pipe recommended use

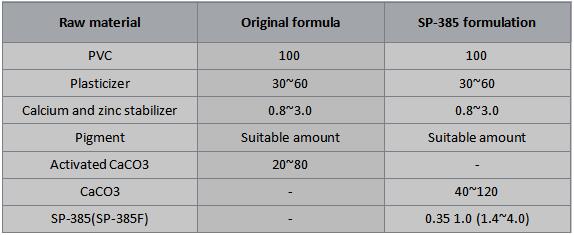

Application in PVC soft products

The above application cases for reference, the user should be based on the actual application of light calcium carbonate / heavy calcium carbonate to make the optimal ratio with the control of calcium carbonate oil absorption value, in order to achieve the most satisfactory performance requirements of the user

SP-385 Safety and Packaging Specifications

SP-385 (SP-385F) has passed SGS certification and meets EU standards.

SP-385 packaging: drum packaging, 180kg/drum and 25kg/drum.

SP-385F packaging: composite PP woven bag, 25kg/bag.