BG360 is a solid modified hyperbranched polymer that is suitable for surface treatment of pigments in inorganic fillers and thermoplastic materials.

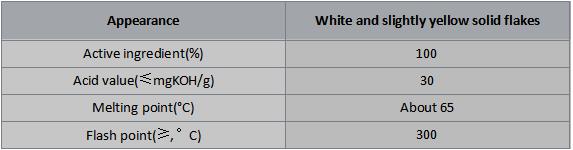

General properties

Typical Applications

BG360 is a surface treatment agent used to improve the dispersibility of powders, suitable for:

▪ Inorganic fillers such as calcium carbonate, talc, kaolin, etc.;

▪ Inorganic pigments such as phthalocyanine blue, iron oxide red, titanium dioxide, etc.;

▪ Organic pigments such as carbon black, phthalocyanine blue, DPP pigments;

▪ Flame retardant fillers such as magnesium hydroxide (MDH), aluminum hydroxide (ATH).

BG360 can also be used in calcium carbonate masterbatch, talc masterbatch, and color masterbatch.

Product Performance

BG360 has many advantages when used for dispersing fillers and pigments:

▪ Increase the loading of pigments and fillers;

▪ Excellent rheological properties;

▪ Enhance the coloring intensity of color masterbatch;

▪ Improve the dispersion performance of inorganic powders in plastics, and enhance the fusion between inorganic powders and polymer materials;

▪ Reduce fiber breakage and strength loss caused by pigments/fillers during spinning;

▪ Reduce the agglomeration of fillers and pigments and prevent further agglomeration;

▪ Improve mechanical properties;

▪ Excellent thermal stability (can reduce the usage of heat stabilizers and antioxidants).

Recommended Applications

Halogen-free flame-retardant cables: Can replace silane coupling agent 172, with good dispersibility and rheology for magnesium hydroxide and aluminum hydroxide.

Polyolefin calcium carbonate masterbatch: Can replace PE wax and aluminum ester coupling agents, with good dispersibility for CaCO3 powder, increase the powder content in masterbatch, and provide friendly mechanical properties, suitable for spinning-grade masterbatch.

Polyolefin talc masterbatch: Can replace aluminum ester, titanium ester, and other coupling agents. BG360 has good dispersibility for talc and can provide composite materials with friendly mechanical properties.

High-filled PVC composites: Can replace CPE and ACR. BG360 can fuse calcium carbonate powder with PVC resin in a friendly way, thereby improving the processing and mechanical properties of PVC composites.

Recommended dosage

Halogen-free flame-retardant cable: based on powder quantity of 0.8% to 1.5%

PVC wire and cable: based on powder quantity of 0.8% to 1.5%

Calcium carbonate masterbatch: formula total amount of 2% to 5%

Talcum powder masterbatch: formula total amount of 2% to 5%

Colorant: relative to 100 parts of pigment, carbon black 15-50 parts, organic pigments 15-50 parts, inorganic pigments 2-5 parts.

Instructions for use

▪ BG360 can be pre-mixed with pigments, fillers, and plastic particles, and then added to the twin-screw extruder for pelletizing after melting and mixing.

▪ BG-360 can also be melted and mixed uniformly with each component material in the internal mixer.

Storage and transportation packaging

BG-360 is a non-flammable and non-explosive product, and storage and transportation should be done according to general chemical products. This product can be stored in the original packaging for at least one year without deterioration.

BG360 packaging specifications: 25kg/bag.