Product Introduction

Product Introduction

CPE (chlorinated polyethylene) is a commonly used impact modifier (toughening agent) for PVC (polyvinyl chloride) products. It is an elastomer obtained by chlorinating special HDPE. The glass transition temperature (Tg) of CPE elastomer is -10℃. When the environmental temperature is below -10℃, CPE changes from rubber elastomer to plastic. When the environmental temperature is below 10℃, the toughening effect of CPE on PVC is significantly reduced or even lost. Moreover, CPE toughens PVC at the expense of significantly reducing the strength, rigidity, modulus, and Vicat softening point of the PVC material. In other words, CPE toughens PVC at the cost of significantly reducing its strength, rigidity, modulus, and Vicat softening point. In addition, CPE has poor compatibility with PVC, high processing melt viscosity, narrow processing range, poor plasticizing effect, and low glossiness of the finished product surface.

SPA-36 is a new type of impact modifier (toughening agent) for PVC obtained through nanomicelle polymerization and self-assembly technology. SPA-36 has good dispersibility, improves the interfacial adhesion and compatibility between SPA-36 and PVC. While SPA-36 toughens PVC, the decrease in strength, rigidity, modulus, and Vicat softening point of the PVC composite material is very small or almost negligible. The strength and toughness of the PVC composite material are better balanced, that is, SPA-36 toughens the PVC composite material to achieve good impact toughness and high strength.

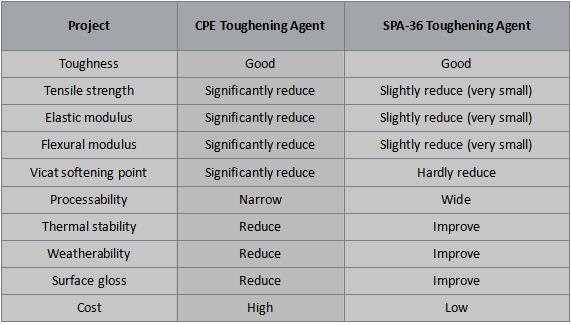

Table 1: Performance Comparison between CPE Impact Modifier and SPA-36 Toughening Agent for PVC

From Table 1, it can be seen that SPA-36 is a good impact modifier (toughening agent) for PVC, which not only has good toughening effect, but also provides better strength, rigidity, and modulus for PVC products.

Comparison of processing and mechanical properties between CPE toughening agent and SPA-36 toughening agent

Comparison of processing and mechanical properties between CPE toughening agent and SPA-36 toughening agent

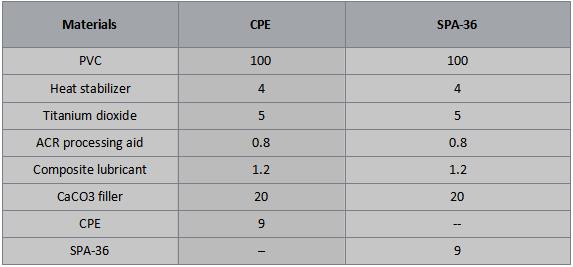

1. Formulation table

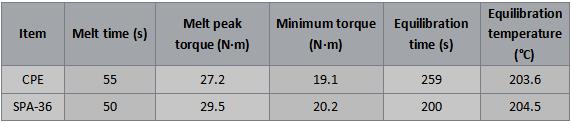

2、Processing Rheological Performance Table

Rheological performance:65g, 60rpm, temperature 185℃

Experimental Data Table

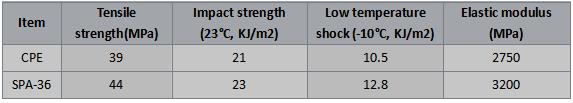

3、Table of Comparison of Physical and Mechanical Properties

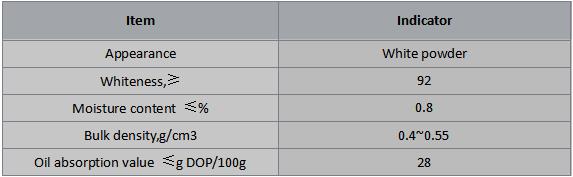

Quality Standards for SPA-36 Toughening Agent Product

Application of SPA-36 impact modifier

▪ Application of SPA-36 impact modifier

▪ PVC water supply pipes

▪ PVC profiles

▪ PVC sheets

▪ PVC roofing tiles

▪ PAC fittings

▪ PVC drainage pipes

▪ PVC reinforced pipes

▪ PVC sheets

▪ PVC electrical conduits

It is suitable for all PVC and CPVC products.

Dosage and Usage of SPA-36 Toughening Agent

Dosage of SPA-36 toughening agent: equivalent to CPE dosage.

Usage of SPA-36 toughening agent: Except for the optimal requirements in the PVC mixing process, the rest of the processing technology is basically the same as CPE.

The recommended optimal process in the PVC mixing process is: during the PVC mixing process, it is recommended to add SPA-36 immediately after adding PVC resin powder, and then add other material components, so that SPA-36 can be fully fused in the gaps between PVC particles, resulting in better toughening effect.

Product Toxicity, Storage, and Packaging

▪ SPA-36 toughening agent is a non-toxic and odorless white powder.

▪ SPA-36 toughening agent is bagged with a packaging specification of 25kg/bag.

▪ SPA-36 toughening agent should be stored in a dry and ventilated place to prevent moisture, and its shelf life is 2 years.